HMI Courses

FactoryTalk View (RSView) ME Level 1 This 32 hour course is designed to give the students the ability to troubleshoot, create, and deploy Factory Talk® View ME projects on industrial terminals. At the end of the class students will understand how to trace objects on the RSView terminal through a PLC program, modify existing objects on any display, and create new objects when needed. We will use the PLC of your choice for the training: SLC-500, PLC-5, or ControlLogix. Students who attend this course will not only troubleshoot objects, but actually configure them so they will have a full understanding of what it takes to make an object interface with the PLC. |

|

In this course, we will look at real world examples of RSView screens from your plant to see how they work on your own systems. Students who attend this course will then learn how to develop professional screens utilizing th graphics and animation features available in RSView, and set up communications between the RSView terminal and the PLC. During the development, students will also learn how to plan a project, set up the screen layouts (including navigation), and deploy the project for the operators to use. |

|

RSView Level 2 (Working with Data) This is the information age. Data can be pulled directly from the plant floor, and logged to a database. Data can then be extracted from the database, and published to management in the form of production reports. This course will teach the students how to set up the logs in RSView, then extract the data in an organized manner, then create the reports based on this data. These reports can be in the form of either a web page, MS Access database project, or a Visual Basic application. |

|

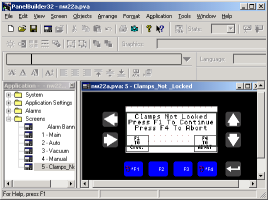

This course is geared toward those who will be working with panelview terminals. During this course, students will learn to establish communication between a panelview and PLC, and practice real world examples of tracing I/O from the panelview terminal through the PLC program. Students who attend this class will also learn how to build screens, and navigate between them. Advanced objects such as bar graphs, gauges, and graphics will help them to build professional screens for the Operator Interface. Students will benefit from this course if they work with the PanelView 300, 300 Micro, 550, 600, or 1000 terminals. |

|

Drives Courses

|

Communication with Variable Frequency Drives This hands-on training course is designed to provide an experienced electrical and knowledgeable PLC person the skills needed to configure and troubleshoot a communication link with the drive. The course begins with an operating motor drive unit controlled by a PLC. The configured operating system is discussed and common communication networks are presented. Course hardware will include a variable frequency AC motor drive workstation with a connected communication module, PLC and computer with programming software. When signing up for the course, make sure you mention the communications that you want to cover and if we do not have the communications module and if you have the module, let us know, we will use your hardware to show how to use the module |

|

CNC Courses

|

Fanuc Electrical Maintenance and Troubleshooting This 4 day, hands-on program is designed to prepare each student with the skills necessary for operation, installation, setup, and basic operational troubleshooting of the Fanuc R30iA Robot Controller and Manipulator |

|

|

Fanuc R30iA – Basic Operations This course is designed to introduce the student to the basic operations of the FanucR30iA robot system. |

|

|

Fanuc R30iA Series – Dispense Tool Operations and Programming This course, designed for maintenance technicians, skilled trades, engineers and supervisors, is to prepare students with the skills to safely program, troubleshoot and repair Fanuc R30iA robot systems configured for dispense operations. |

|

|

Fanuc R30iA Series – Operations for Technicians This course is designed for operators, production staff, maintenance technicians, skilled trades, engineers or supervisors who need to learn the basics of the Fanuc R30i robotics system. The course contains a minimum of 50% hands-on time with an applicable robotics system. |

|

|

C-Flex Operations and Maintenance This course is designed for participants to learn operation and maintenance functions of the Fanuc C-Flex robotics system. |

|

|

Mitsubishi G Code (Tool Path) Programming This class will teach students the fundamentals of basic programming. Students learn Cartesian Coordinate Systems, G codes, basic M codes, word address, canned cycles, cutter radius compensation, and sub programs. Participants will be given many different examples, as well as write many programs. Safety lines and technique will also be taught. This course is applicable to the Mitsubishi 500 and 600 series. |

|

|

Okuma G Code (Tool Path) Programming This class will teach students the fundamentals of basic programming. Students learn Cartesian Coordinate Systems, G codes, basic M codes, word address, canned cycles, cutter radius compensation, and sub programs. Participants will be given many different examples, as well as write many programs. Safety lines and technique will also be taught. This course is applicable to Okuma OSP 5000, 5020, 7000, 700I and U10I models. |

|

|

Okuma Mechanical Maintenance for Lathe This course is designed for the Maintenance person who has had only limited exposure to Okuma lathes or for those who are first-time CNC machine tool users. |

|

|

In this course, students will explore the creation and use of macros and will learn about various options available on the system. |

|